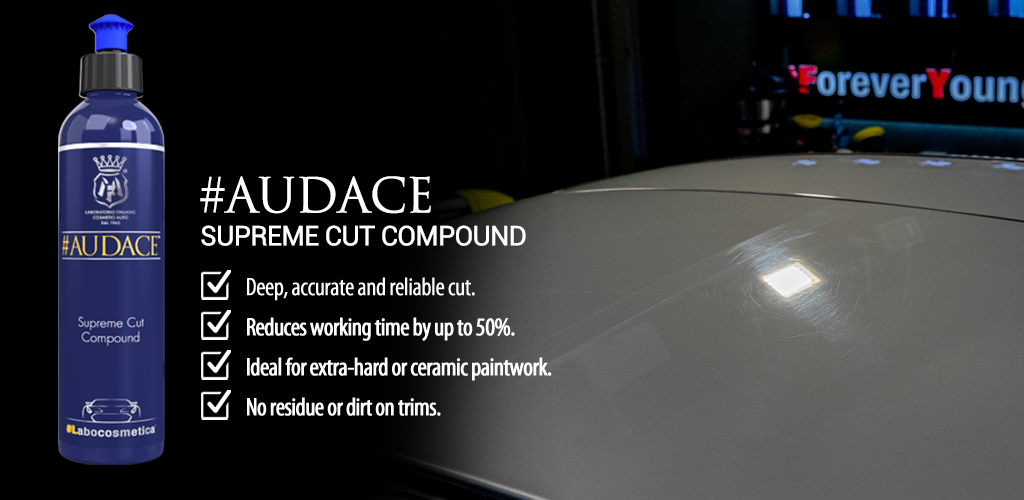

#AUDACE

SUPREME CUT COMPOUND

#AUDACE is a water-based compound with high cutting capacity at low speed. This is possible thanks to a selection of new generation abrasives, which will allow you to cut using a random orbital polisher similar to those obtained using a rotary polisher, thus reducing required time by up to 50% compared to traditional compounds. With #AUDACE, required time can be reduced by up to 50% compared to traditional compounds.

Share

► Deep, accurate and reliable cut.

► Reduces working time by up to 50%.

► Ideal for extra-hard or ceramic paintwork.

► Medium polish refinish.

► No residue or dirt on trims.

► Highly versatile product suitable for different surfaces depending on the type of pad used.

► ODOURLESS and low VOC content.

►#AUDACE is a highly effective water-based cutting compound that offers excellent results even at low speeds.

Thanks to the use of new innovative abrasives, it is now possible to achieve cutting results with a random orbital sander that rival the performance of a rotary sander, guaranteeing shorter working times. #AUDACE can reduce working times by up to 50% compared to traditional compounds. This versatile compound is a top choice among detailers thanks to its capacity to solve the most challenging problems, saving both time and money. This is thanks to the use of the innovative “Cold Cut Technology” which is able to eliminate defects at low speeds (1200 rpm with rotary sander or speed 4.5 with an orbital sander), reducing the risk of holograms, shortening working times, offering greater ease of use and using less product. #AUDACE is particularly effective on hard or new generation ceramic surfaces but when paired with the right pad offers excellent versatility on any surface. #AUDACE has been designed to eliminate deep scratches, even sandpaper marks of up to 1000 grit.

Incredibly, despite the high cutting capacity the product leaves a medium-polish refinish. #AUDACE is easy to remove even on tacky paints and doesn’t leave dust or residue. #AUDACE is free from paraffins or fillers, doesn’t tarnish trims, can be applied easily and confidently and leaves a medium-polish finish. When paired with our Super Finish Primer #FIERO the job can be compelted in just 2 steps.

#AUDACE thanks to its “ColdCut Technology “, with rotary can be worked starting from 400-600 rpm up to 1000-1200, the latter will be the speed ideal for having an excellent compromise between cut and finish even with the use of wool pads which, as is well known, leave no way out for the creation of holograms.

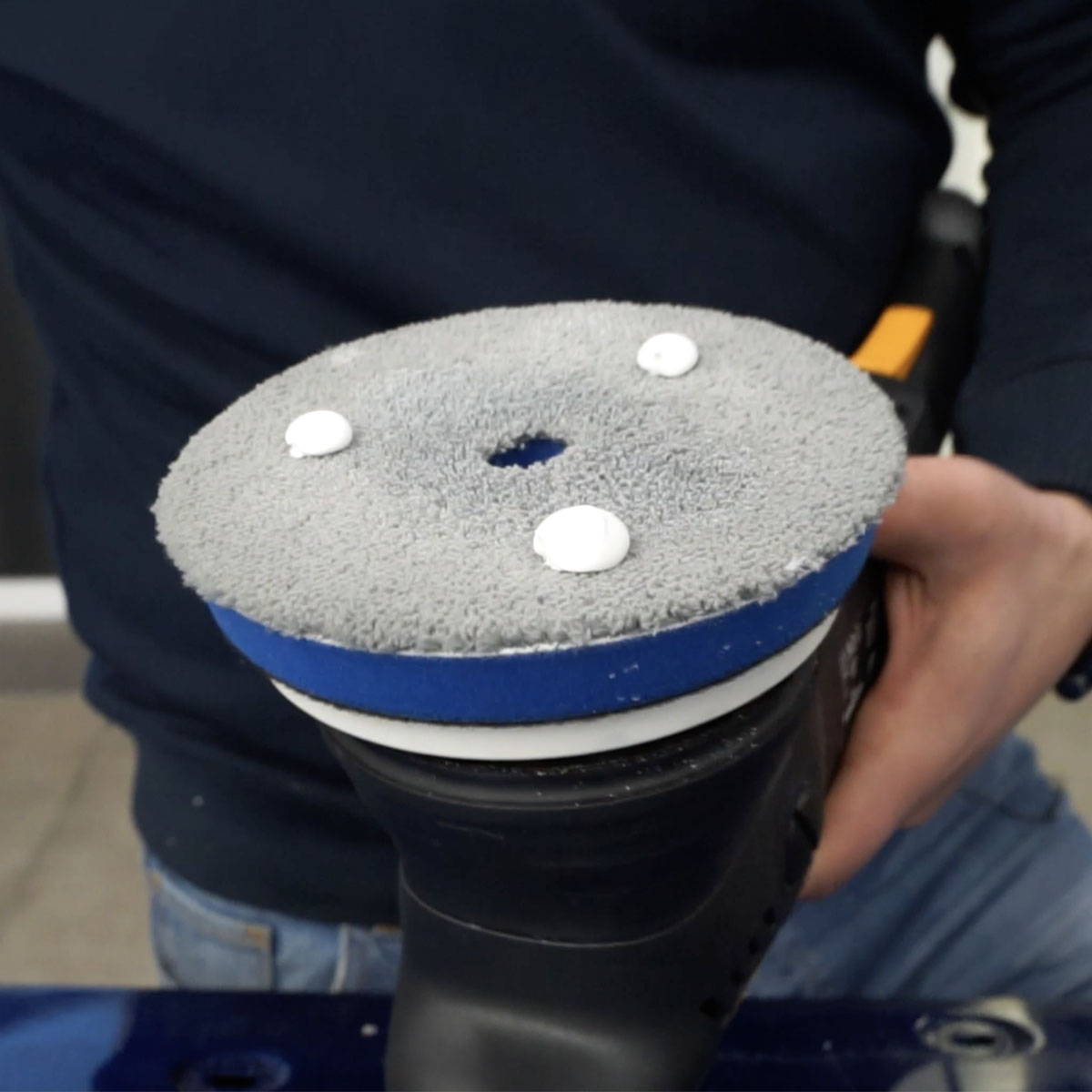

For the use of #AUDACE with a wool pad, we recommend an amount equal to 4 drops as it has greater absorption, while for the sponge pads 3 drops will be useful as it has less absorption. During processing, we recommend cleaning the pads frequently in order to make the most of the product’s performance and avoid the formation of dust.

#AUDACE can be worked with a random orbital starting from speed 1 useful for spreading the product on the surface to be machined about 40X40 cm, then increase to speed 3 so as to facilitate the start of the cut by the abrasive reaching maximum cutting performance at speed 5 until the compound is exhausted. To have a greater cutting capacity, with the random orbital we recommend using the “HybridPad” pad, an excellent ally for the hardest surfaces using 3 drops of product at a time, while for surfaces that require a smaller cut it will be possible to use the White or Blue. During processing, we recommend cleaning the pads frequently in order to make the most of the product’s performance and avoid the formation of dust.

Instructions:

#AUDACE can be worked with random orbital starting from speed 1 useful for spreading the product on the surface to be worked 40X40 cm approximately .

#AUDACE can be worked with random orbital starting from speed 1 useful for spreading the product on the surface to be worked 40X40 cm approximately.

To have a greater cutting capacity , with random orbital we recommend using the “HybridPad” pad, an excellent ally for harder surfaces using 3 drops of product at a time. While for surfaces that require a minor cut it will be possible to use the pad in White or Blue sponge.

We recommend during processing to frequently clean the pads in order to make the most of the product’s performance and avoid the formation of dust.

Results:

Dilution:

Car parts

Materials

Type

P102 Keep out of reach of children.

#AUDACE

TIME SAVING

With #AUDACE it is possible to reduce processing times by up to 50% compared to

to traditional compounds.

VERSATILE COMPOUND

This versatile compound is a top choice among detailers thanks to its capacity to solve the most challenging problems.

- Reduce working times by up to 50%

- Saving money

- Excellent results even at low speeds

#AUDACE is a water-based compound with a high cutting capacity, even at low speeds. All this thanks to a selection of newly developed abrasives thanks to which you will be able to obtain cutting performance with random orbital comparable to those with the use of a rotary press, ensuring reduced processing times.